In this article, we’ll break down the differences between a purchase requisition vs purchase order, two critical documents in the procurement process. Understanding these distinctions can streamline your purchasing and improve operational efficiency, especially in industries like construction and manufacturing.

What is a Purchase Requisition?

A purchase requisition is an internal document used when an employee or department requests to make a purchase on behalf of the company. It acts as a formal request to the purchasing department to procure goods or services.

Key Features of a Purchase Requisition:

- Purpose: It notifies the purchasing department of required materials or services.

- Details Included: The requesting employee or department, the cost of materials, quantities needed, reasons for the purchase, and the suggested supplier.

- Approval Process: Department managers or purchasing heads review and approve the requisition before it proceeds further.

- Internal Use: This document remains within the organisation and is not shared with external parties.

Example Use Case:

In construction, a site manager might submit a requisition form to request materials such as concrete or safety equipment. The requisition ensures that these needs are evaluated, budgeted, and approved before procurement.

What is a Purchase Order?

A purchase order (PO) is an external document sent to a supplier after a purchase requisition has been approved. It formally confirms the purchase, specifying terms and conditions of the transaction.

Key Features of a Purchase Order:

- Purpose: It serves as a legally binding agreement between the buyer and supplier.

- Details Included: Company name, supplier details, a description of goods or services, quantities, agreed prices, payment terms, and delivery instructions.

- External Use: This document is shared with the supplier to initiate the procurement process.

Example Use Case:

Once a requisition for safety helmets is approved, the purchasing department sends a purchase order to the supplier. The PO includes the required quantities, agreed price, and delivery timeline.

Purchase Requisition vs Purchase Order Key Differences

| Aspect | Purchase Requisition | Purchase Order |

|---|---|---|

| Purpose | Internal request for approval to purchase materials | External confirmation of an order with a supplier |

| Audience | Used within the organisation | Sent to suppliers |

| Details Included | Requesting department, cost, quantity, reason | Description, price, supplier, terms, delivery |

| Legal Binding | Not legally binding | Legally binding |

| Timing | Submitted before approval | Sent after approval |

Benefits of Using Both Documents

Purchase Requisitions:

- Fraud Prevention: Reduces the risk of unauthorised purchases.

- Budget Management: Ensures all purchases are pre-approved and align with budgets.

- Transparency: Creates an internal record of requests, improving accountability.

Purchase Orders:

- Legal Clarity: Serves as a contract between buyer and supplier, minimising disputes.

- Cost Control: Tracks committed costs and prevents duplicate payments.

- Efficiency: Enables automated tracking through procurement software.

Why Are These Documents Important in Construction?

In construction, where materials and equipment often form a significant portion of project costs, having a clear procurement process is essential. Purchase requisitions ensure requests are justified and approved, while purchase orders provide a reliable record for suppliers and project managers.

For example, without a requisition and PO system, miscommunications can lead to delayed deliveries, incorrect materials, or overspending. Implementing both documents helps construction businesses:

- Avoid costly errors.

- Negotiate better deals through bundled orders.

- Maintain project budgets and timelines effectively.

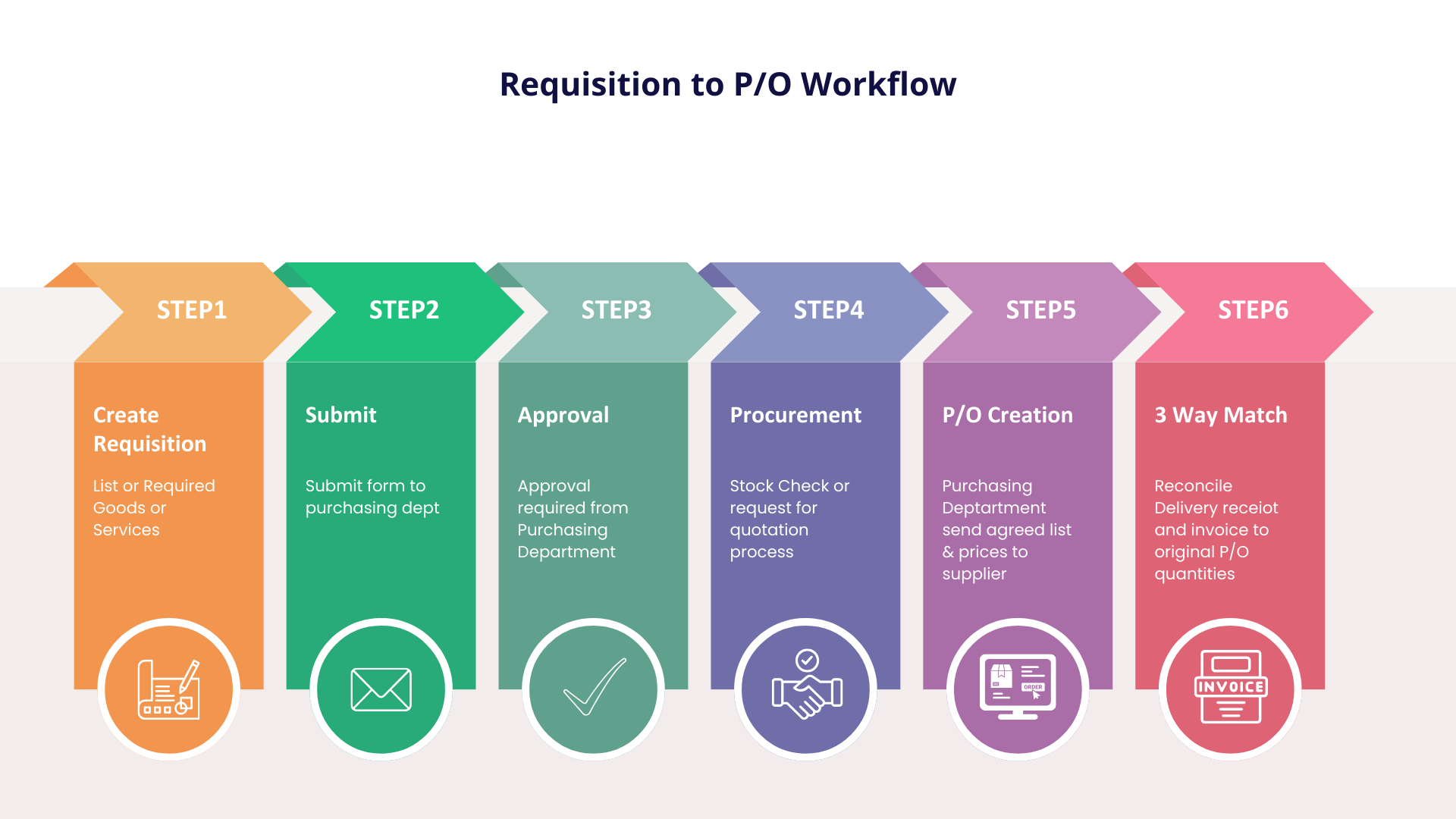

Requisition to Purchase Order Workflow

Here is a step-by-step breakdown of the workflow from a purchase requisition to a purchase order:

Step 1: Create Requisition

- List the goods or services required for the project or department.

- Ensure all details, such as item quantities and specifications, are included.

Step 2: Submit

- Submit the purchase requisition form to the purchasing department for review.

- This is an internal process to formally notify the purchasing team.

Step 3: Approval

- The purchasing department or an authorized manager reviews the requisition.

- Approval is granted if the requisition aligns with budget and business needs.

Step 4: Procurement

- Conduct a stock inventory check or initiate a request for quotation (RFQ) process to evaluate supplier options.

- This step ensures that the most suitable supplier or vendor is chosen.

Step 5: P/O Creation

- Once procurement is finalised, a Purchase Order (PO) is created.

- The PO is sent to the chosen supplier, detailing quantities, agreed prices, and delivery terms.

Step 6: Three-Way Match

- Upon receiving goods or services, match the delivery receipt, purchase order, and supplier invoice.

- This ensures consistency and accuracy before payment is processed.

Digitising the Process with LiveCosts

Modern businesses, especially in construction, benefit from digital tools that simplify procurement. LiveCosts offers solutions to digitise purchase requisitions and purchase orders, providing real-time visibility into project costs and reducing manual administrative work.

Features of LiveCosts:

- Requisition Tracking: Digitise requests with approval workflows.

- Purchase Order Management: Generate and manage POs efficiently.

- Job Costing: Track expenses against project budgets seamlessly.

- Integration: Works with existing accounting tools.

Conclusion

Both purchase requisitions and purchase orders are vital components of an efficient procurement process. While requisitions help justify and approve purchases internally, purchase orders formalise agreements with suppliers. Leveraging tools like LiveCosts can streamline these processes, saving time and money while ensuring greater transparency and accountability.

Ready to take the next step ?

Learn more about LiveCosts

Written By :

Niall Brennan

Product Manager & Founder @Livecosts.com